How build angle and post-processing impact roughness and corrosion of additively manufactured 316L stainless steel | npj Materials Degradation

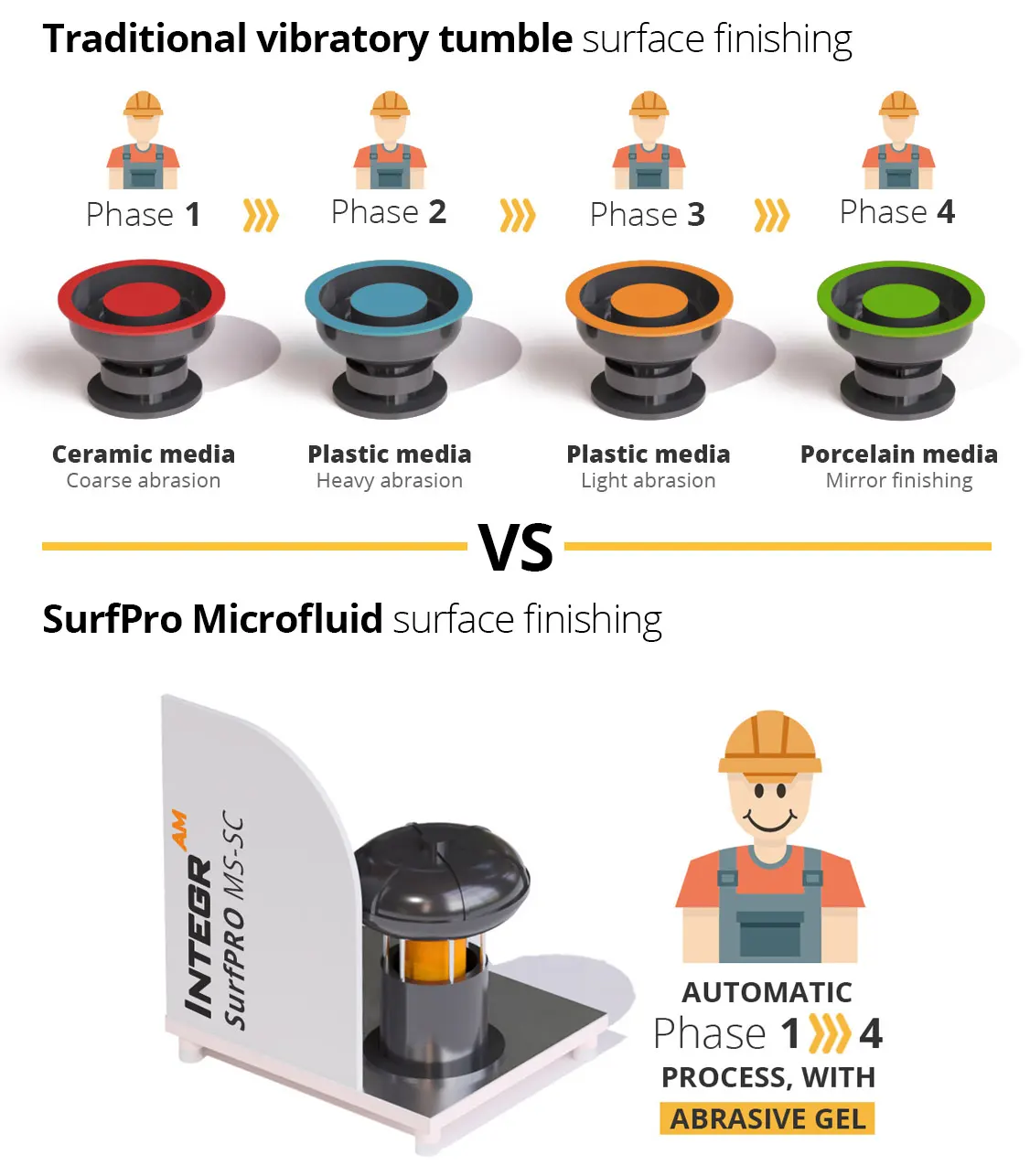

SurfPRO tools: Surface finishing systems for SLS®, MJF®, FDM®, DMLS® and SLM® - Spengler productivity tools

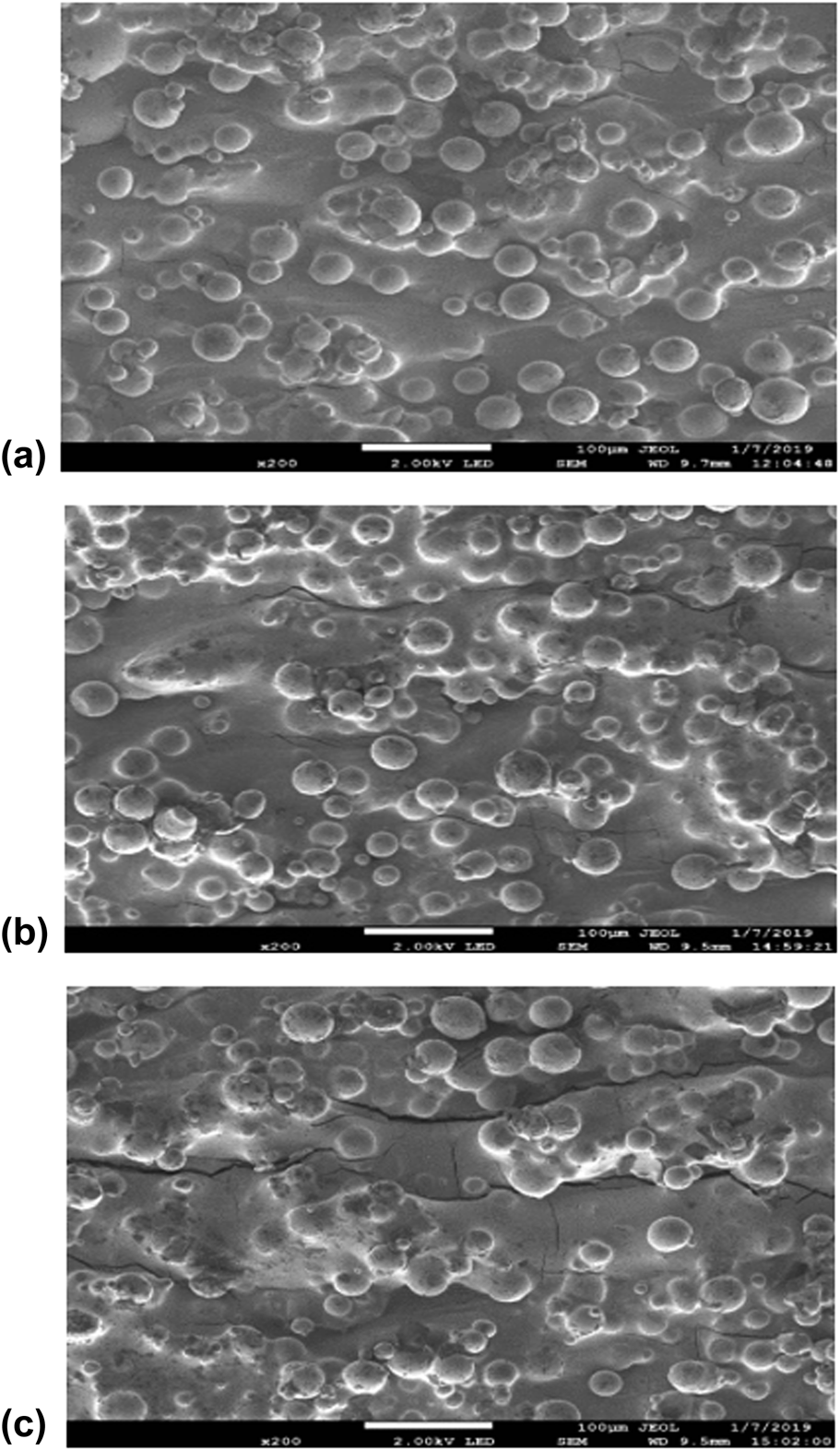

The SEM surface morphology images of SLM-processed 316L stainless steel... | Download Scientific Diagram

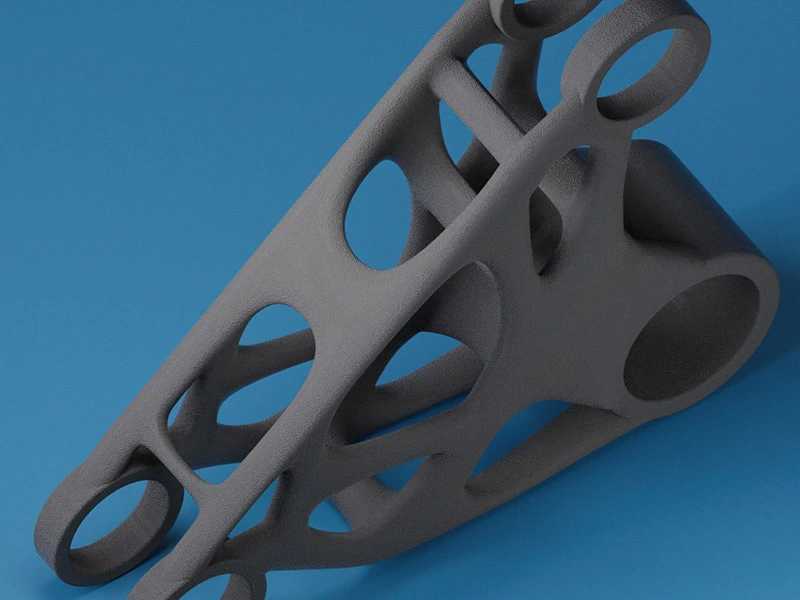

Comparing Surface Finish and Post-Processing Methods for SLM 3D Printed Parts - 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing

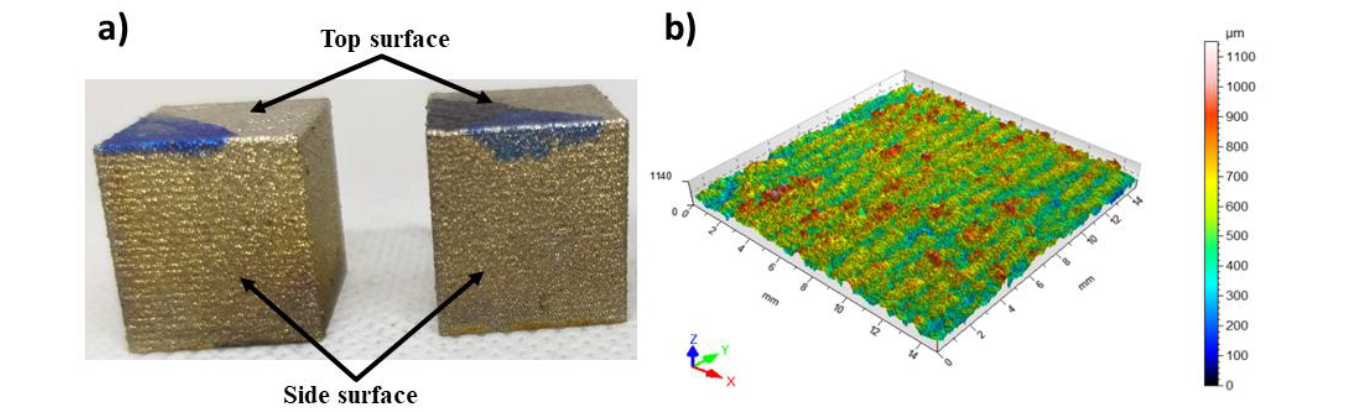

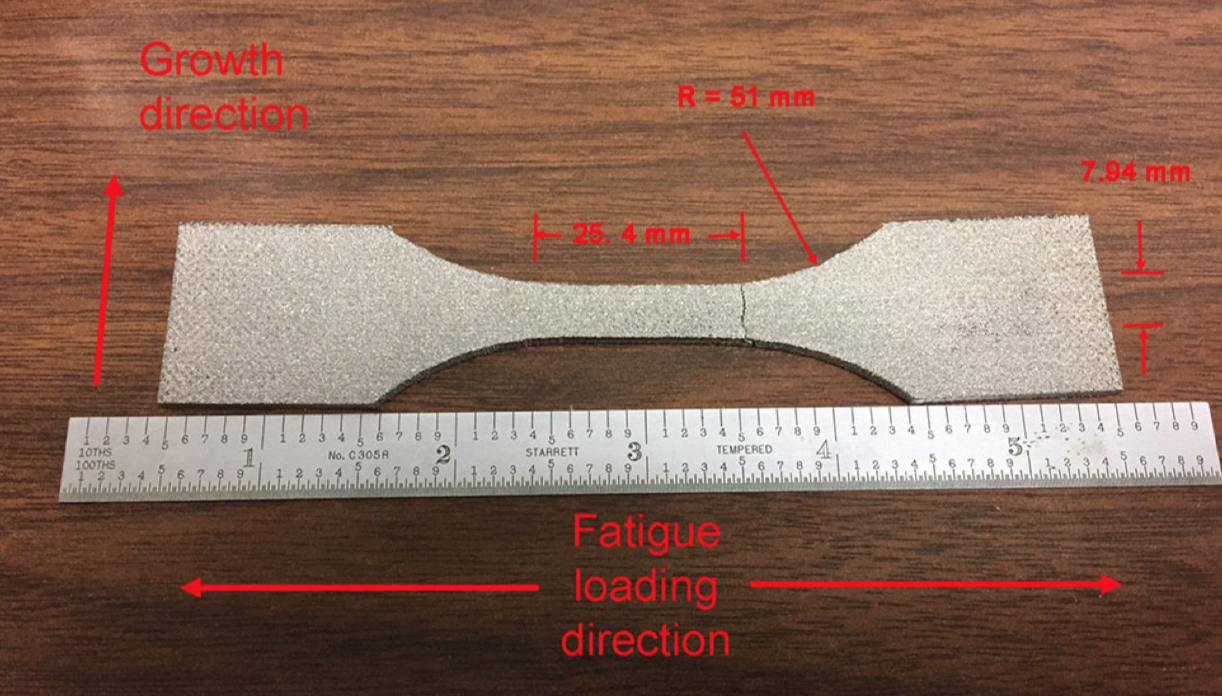

Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts - ScienceDirect

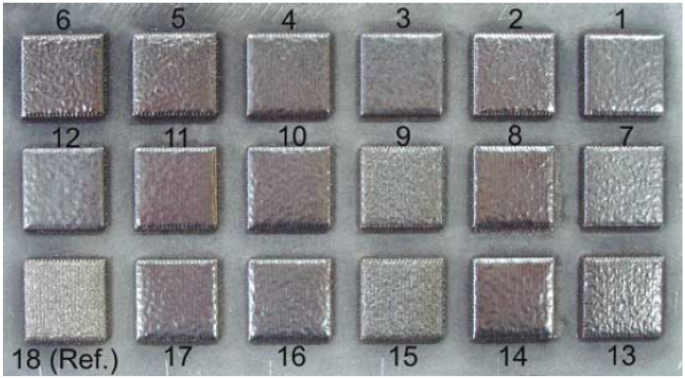

![PDF] EFFECTS OF PARTICLE SIZE DISTRIBUTION ON SURFACE FINISH OF SELECTIVE LASER MELTING PARTS | Semantic Scholar PDF] EFFECTS OF PARTICLE SIZE DISTRIBUTION ON SURFACE FINISH OF SELECTIVE LASER MELTING PARTS | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/cdb60ab507d94184b32bb2432ee61d4216a39cb7/2-Figure1-1.png)

PDF] EFFECTS OF PARTICLE SIZE DISTRIBUTION ON SURFACE FINISH OF SELECTIVE LASER MELTING PARTS | Semantic Scholar

Laser polishing: a review of a constantly growing technology in the surface finishing of components made by additive manufacturing | The International Journal of Advanced Manufacturing Technology

1. Introduction Additive Manufacturing (AM) is a recent innovation in manufacturing technology with development beginning in the

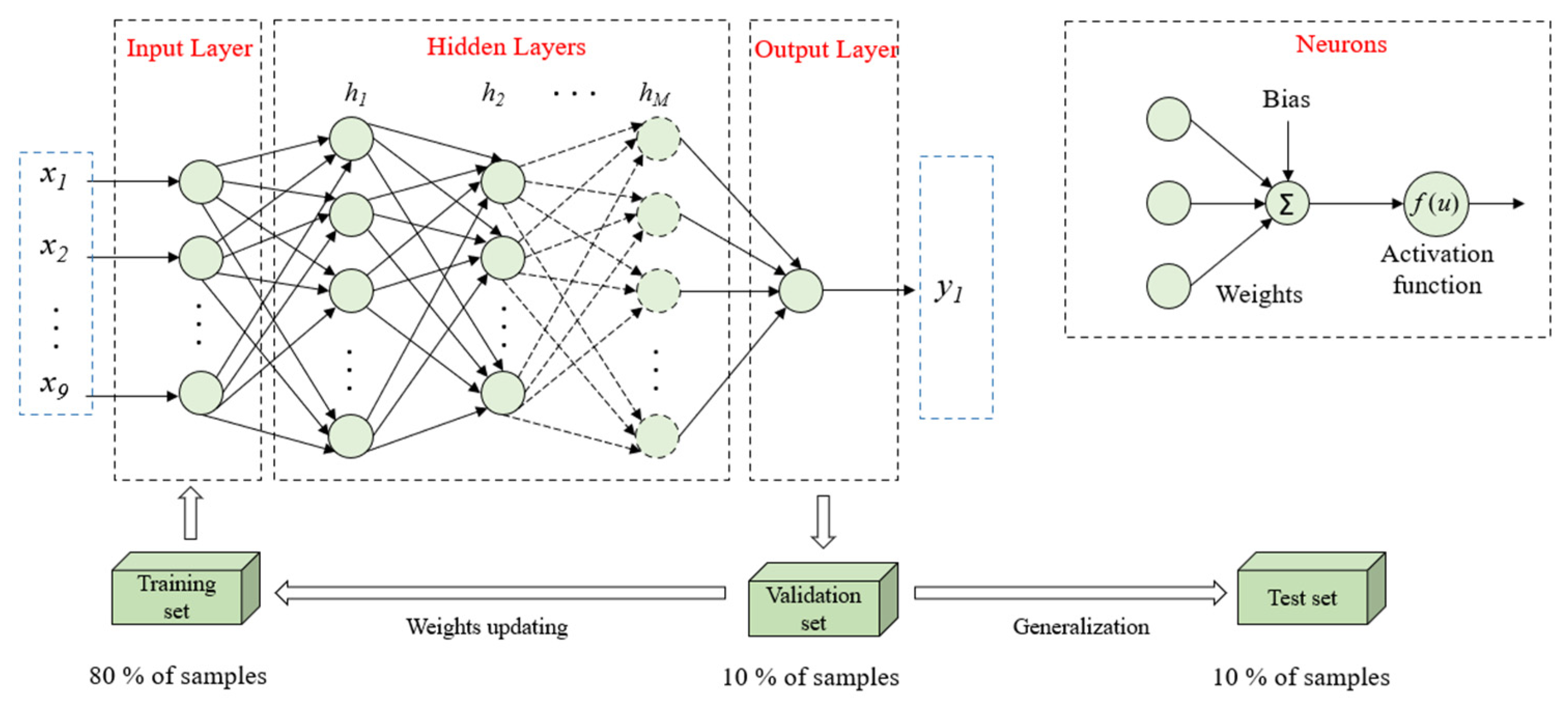

JMMP | Free Full-Text | Prediction of Surface Roughness of SLM Built Parts after Finishing Processes Using an Artificial Neural Network

Influence of selective laser melting scanning speed parameter on the surface morphology, surface roughness, and micropores for manufactured Ti6Al4V parts | Journal of Materials Research | Cambridge Core

SLM parameters for producing benchmark for dimensional accuracy and... | Download Scientific Diagram

Surface roughness optimisation for selective laser melting (SLM): Accommodating relevant and irrelevant surfaces - ScienceDirect

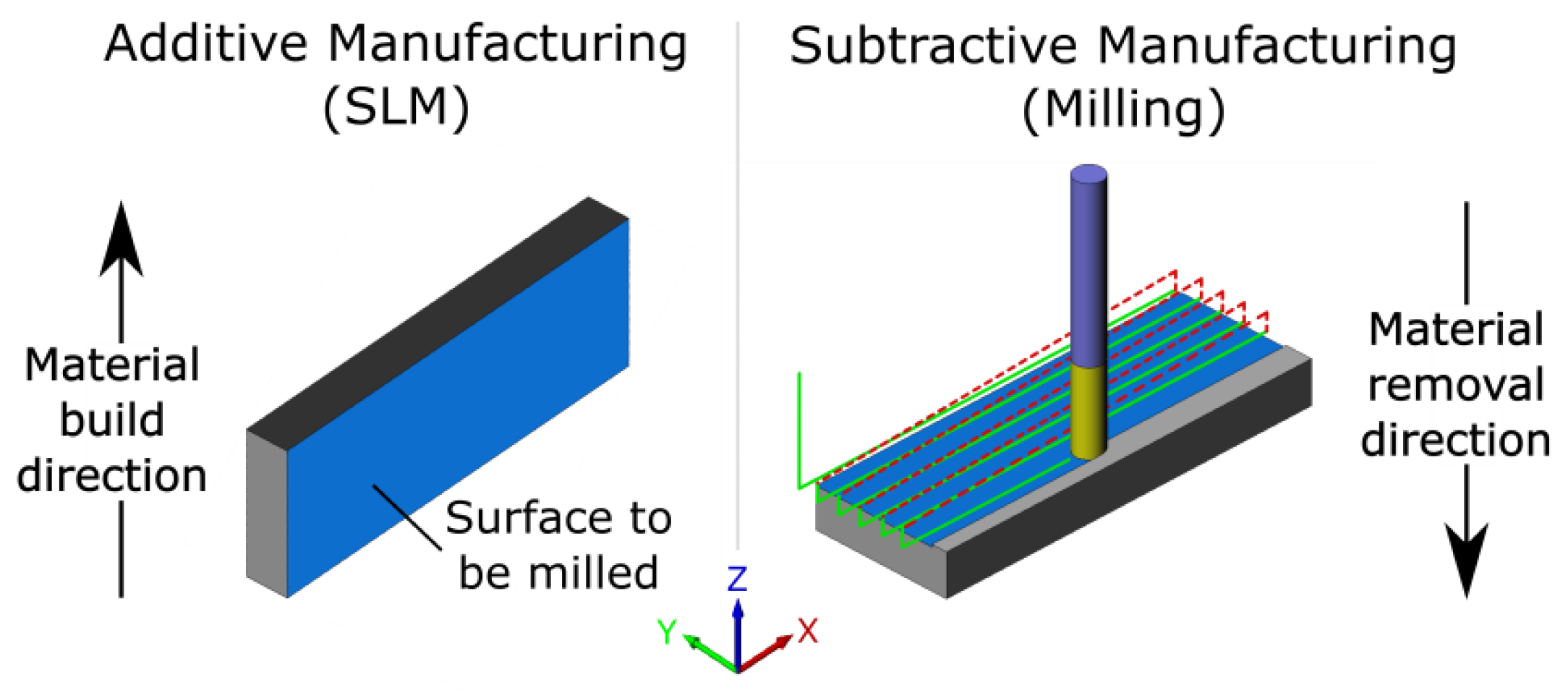

Materials | Free Full-Text | Research and Optimization of Surface Roughness in Milling of SLM Semi-Finished Parts Manufactured by Using the Different Laser Scanning Speed

Surface Treatment of Powder-Bed Fusion Additive Manufactured Metals for Improved Fatigue Life - REM Surface Engineering

Comparing Surface Finish and Post-Processing Methods for SLM 3D Printed Parts - 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing

Visual inspection on EBM (a) and SLM (b) products; high magnification... | Download Scientific Diagram

Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts - ScienceDirect

Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts - ScienceDirect